POINT 430 VINYL FIX is a bi-component vinyl ester styrene free chemical anchor for structural/ high loads, CE marked and ETA assessed for use in concrete.

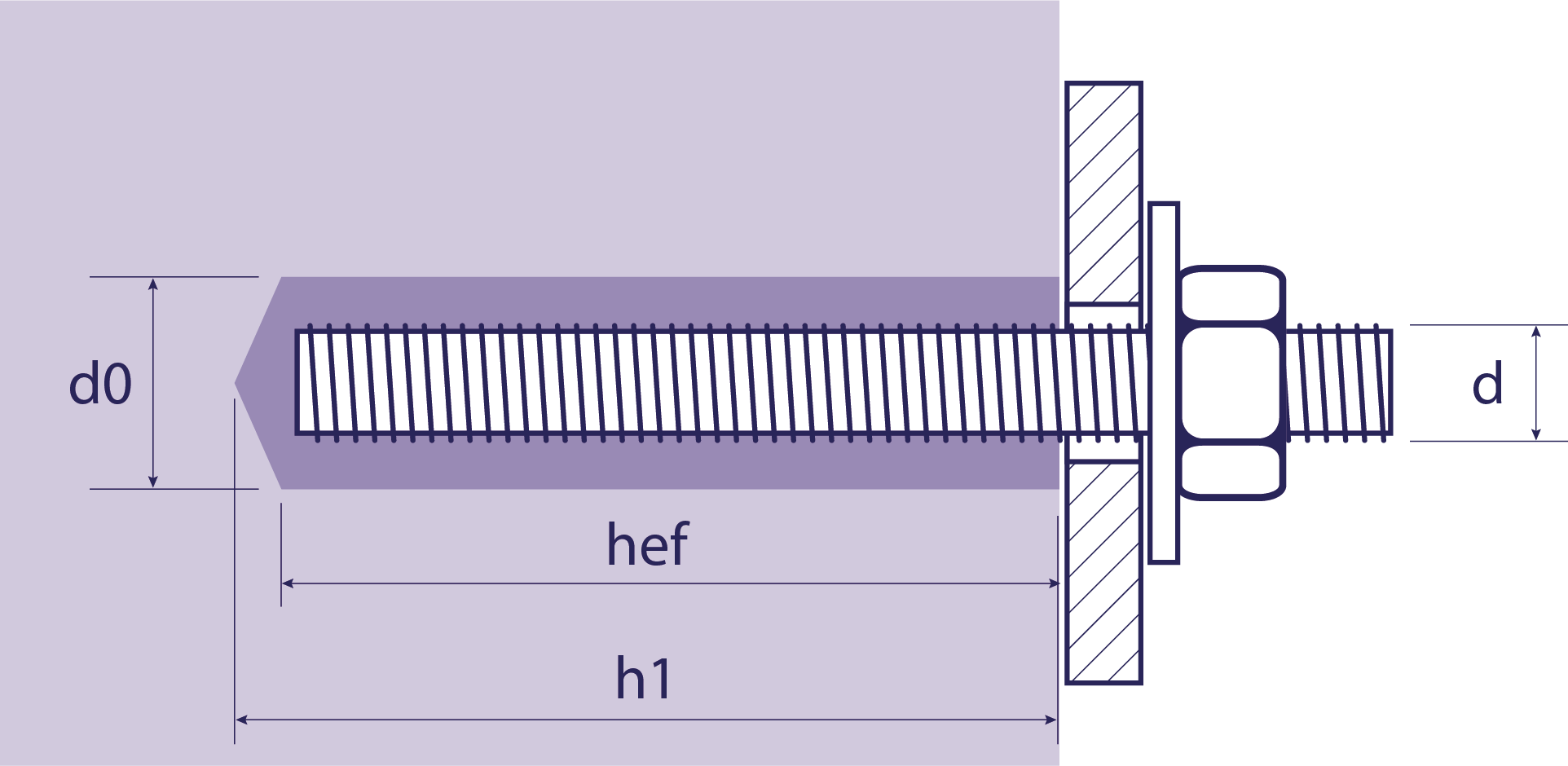

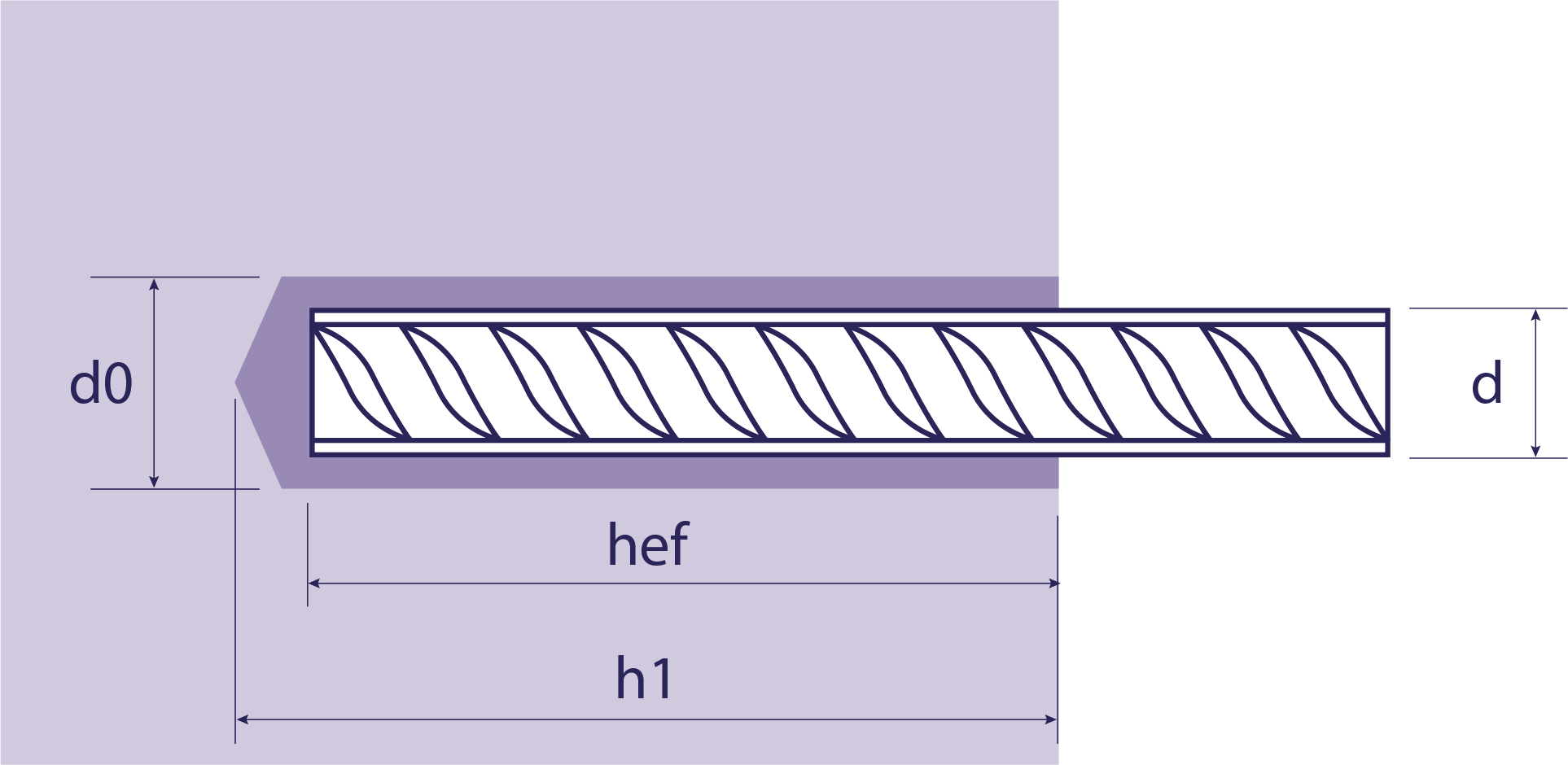

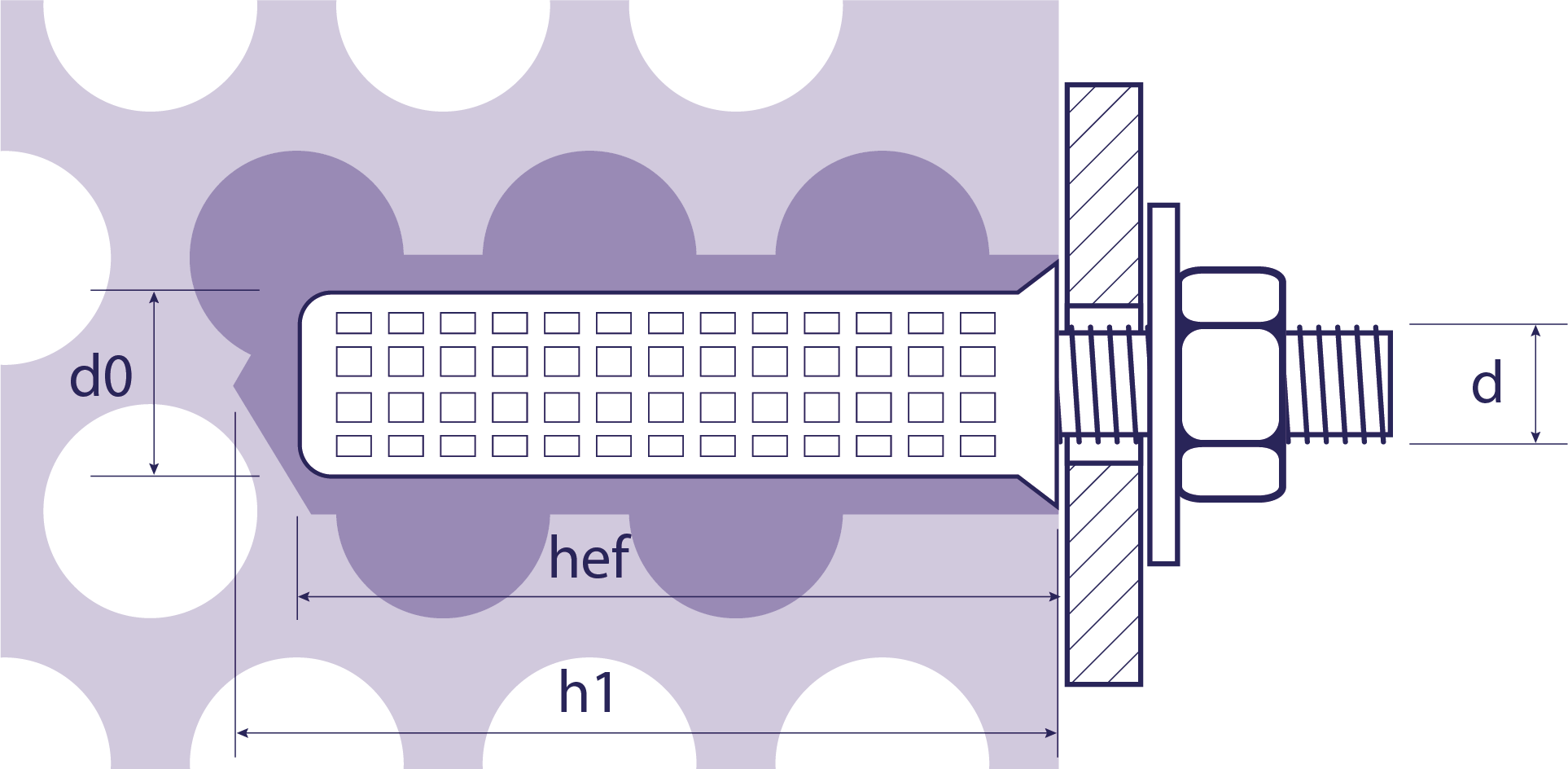

It is certified for threaded rods to be used in non-cracked concrete from diameters M8 to M30, in cracked concrete from diameters M10 to M20, in solid masonry from diameters M8 to M16, in hollow masonry from diameters M8 to M12 and in timber from diameters M8 to M16.

It is certified for rebars to be used in non cracked concrete from diameters Ø8 mm to Ø32 mm and for post-installed rebar connections in reinforced concrete for diameters from Ø8 mm to Ø32 mm.

This resin has seismic qualification, fire resistance and chemical resistance. It can be used when base material temperature is between -10°C and +40°C. Suitable for use in wet concrete and flooded holes.

Due to its strong adhesion and ease of penetration into holes and hollow materials, the resin allows a secure attachment without expansion and without stresses in the base material, which allows you to make fixings close to the corners and edges of base material.

Cleaning:

Drill the hole and check it’s perpendicularity. Blow the hole with an appropriate pump blower (or compression air), clean the lateral surface of the hole with an appropriate steel brush, blow again in the hole until there is no dust and/or any residual material inside. We strongly recommend use of the steel brush to clean hole sides.

Opening:

Unscrew the front cup, pull-out the steel closing clip according to the following operations: 1) Insert the mixer in the eye of the plastic extractor. 2) Pull the extractor to unhook the steel closing clip of the foil. After that, screw on the mixer and insert the cartridge in the gun. Use protections for hands and face.

Cartridge preparation:

Use the correct dispenser.

Before starting to use the cartridge, eject a first part of the product, being sure that: 1) Trough the mixer (transparent) see that the flux of product is compound of the part A (white color) end of part B (black color). 2) The two components are completely mixed. The complete mixing is reached only after that the product, obtained by mixing the two component, comes out from the mixer with an uniform color. Now the cartridge is ready to be used.

Injection:

1) Inject resin into the hole up to fill it 2/3rds. In hollow bricks use the plastic sleeve and inject the resin inside.

2) Before insert the rod, verify that the element is dry and free oil and other contaminants. Insert threaded stud turning back and forth to avoid presence of air in the fitted hole.

3) For the installation and the following anchor load phase, respect the open time and curing time detailed in the technical data sheet and in the label of the product.

4) Before to load the anchor, check the hardened of the product.

5) The cartridge can be used again screwing the cup and replacing the mixer. Remember to eject a first part of the product, see point 3.

Store in a vertical position in a dry place at a temperature between +5 °C and +30 °C. Expiry date – 15 months from the date of manufacture, in compliance with the storage rules. Quantity in a box – 15 pcs. Quantity in the palette – 960 pcs. Transport temperature from +5 °C to +30 °C.